ABBIN NATUURSTEEN: Assembling stones with 3M VHB GPH double-sided tape

Julien Pierre

Etilux

Located in Essen, a stone’s throw from the Dutch border, Abbin is a company specialised in the design of products made from natural stone, in particular Hainaut blue stone from the quarries in Soignies.

You won’t find any standard dimensions at Abbin. The company makes everything to measure, customised for the customer: shower trays, kitchen worktops, washbasins, stairs, pool and pond edges, door thresholds and window sills.

Delivering bespoke products to customers requires incredibly precise work, right down to the millimetre. As the end consumer pays a lot of money for this type of design, it is only natural that they demand a perfect finish and fast delivery.

Gluing the stone

During the manufacturing process for certain products, such as door thresholds, it is necessary to glue two pieces of stone together. Initially, Abbin used a resin-based adhesive. The problem with using this adhesive is that the final hardness is only achieved after 24 hours of drying at 20°C. This takes a long time and requires that this section be immobilised on a surface that cannot be used for working on other elements. As a result, production is rather time-limited.

Gert van Loon, the production manager at Abbin Natuursteen, explains: ‘We had to find a faster solution for gluing the stone, while maintaining the adhesive quality.‘ With this in mind, Abbin turned to Etilux. Thanks to the expertise of Samuel Scheunis, the manager of the ‘Adhesives & Packing’ department, Etilux provided the answer to Abbin’s problem.

A comprehensive solution with 3M™ products

Abbin found the solution within the range of 3M™ industrial adhesives distributed by Etilux: the ultra-resistant VHB GPH double-sided tape, which is cut to size. A quick and easy permanent bonding system that is effective and durable, which can effectively replace welds, rivets or bolts and is ideal for bonding stone, a difficult material to assemble.

The steps in the gluing process

In real terms, the blue-stone elements are dried and brought to the preparation table after being cut to size with pressurised water. For optimal bonding, the portion to be bonded must be perfectly clean and any residue must be removed using the 3M™ VHB cleaner and 3M™ wipes. This removes any dust and small stone chips that result from the cutting process.

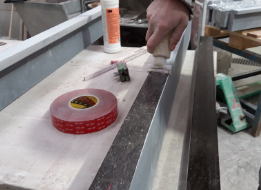

Once the stone is perfectly clean, a thin layer of 3M™ VHB 94 primer is applied to the two surfaces being glued. This will make the stone less porous and facilitate adhesion. The thinner the layer, the greater the level of adhesion. Application is quick and easy thanks to the applicator.

The next step is to place the 3M™ VHB GPH double-sided tape. This is a multi-purpose acrylic adhesive foam, which is resistant to high temperatures. This permanent bonding system adheres to a wide range of materials, even at low temperatures. The adhesive is sensitive to pressure. This means that the user must apply a lot of pressure once it is applied, in order to allow the foam to adhere to the bonding surface. Next, after removing the protective film, the second stone can be placed. The assembly of the two blue stones is complete. You will need to wait approximately 40 minutes at room temperature for the tape to solidify. The bond between the two pieces can then be placed outside in any weather.

A Belgian story

Abbin has many customers in the Land of Tulips, due to its proximity to the Dutch border. It has the distinction of working with blue stone from quarries in the province of Hainaut, and calls on Etilux, a Liège-based company, to take up the challenge posed by assembling its stone pieces. A beautiful Belgian story!

Technical framework

Cleaner 3M™ VHB

This isopropyl-alcohol-based primer has been developed for cleaning surfaces that are being prepared for bonding. The advantage of this cleaner is that it does not leave any traces, does not damage most painted surfaces and can be used for most plastic surfaces (prior testing is essential).

Track your chassis production with RFID

Discover our e-shop

A large catalog of products and services available 24/7