What is the difference between flat-head and near-edge? 20 April 2021

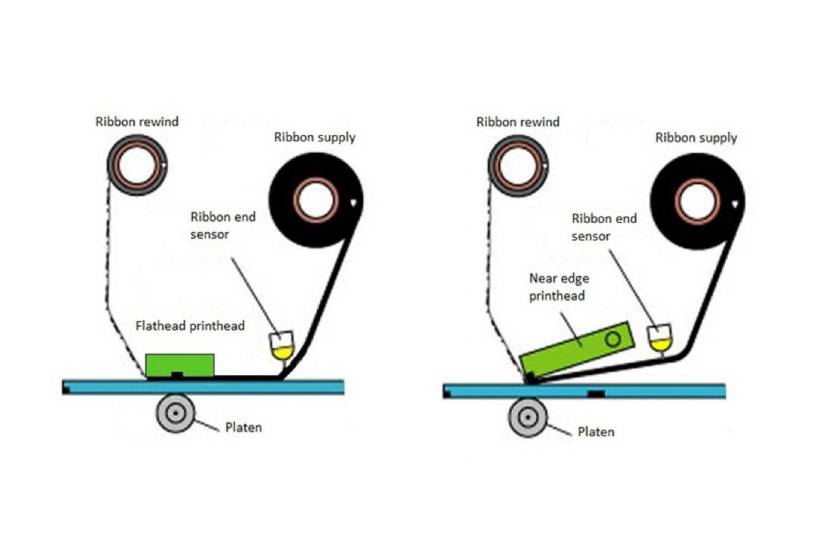

In simple terms, the main difference between flat-head and near-edge lies in the way in which the print-head comes into contact with the ribbon and the surface being printed. With a flat-head printer, the print-head is flat against the ribbon and the material. Using this technology, the ribbon and the printing surface remain in contact over a short distance once they have crossed the print-head’s heating zone, before they are separated.

However, with near-edge technology, the print-head is tilted at a 45-degree angle, with the heating elements being located on the edge of the print-head. This angular approach means that the ribbon and the support only remain together for a very brief period before they are separated, which makes the printing process a lot faster.

Why choose one over the other?

In other words, why choose to buy a near-edge printer? The answer is simple: near-edge printing makes it possible to print on a wide range of label materials. This allows for better-quality printing with smaller fonts and greater speed.

If you need to print on different and unusual materials, such as plastic labels, near-edge printers work a lot better thanks to the floating print-head, which automatically adapts to the thickness of the materials being printed. This means that the technology tends to make the print-head more tolerant to changes in thickness in the label material.

Read also

All the news

Etilux will be present at Empack Namur 2024

How to store and handle your rolls of labels ?

The labelling of chemical products

Discover our e-shop

A large catalog of products and services available 24/7